Transformation through collaboration: Connections for a shared world

Innovation Issue 37: Fall 2022

Mimicking meat: Creating a next generation plant protein

Partner to Innovate

Mimicking meat: Creating a next-generation plant protein

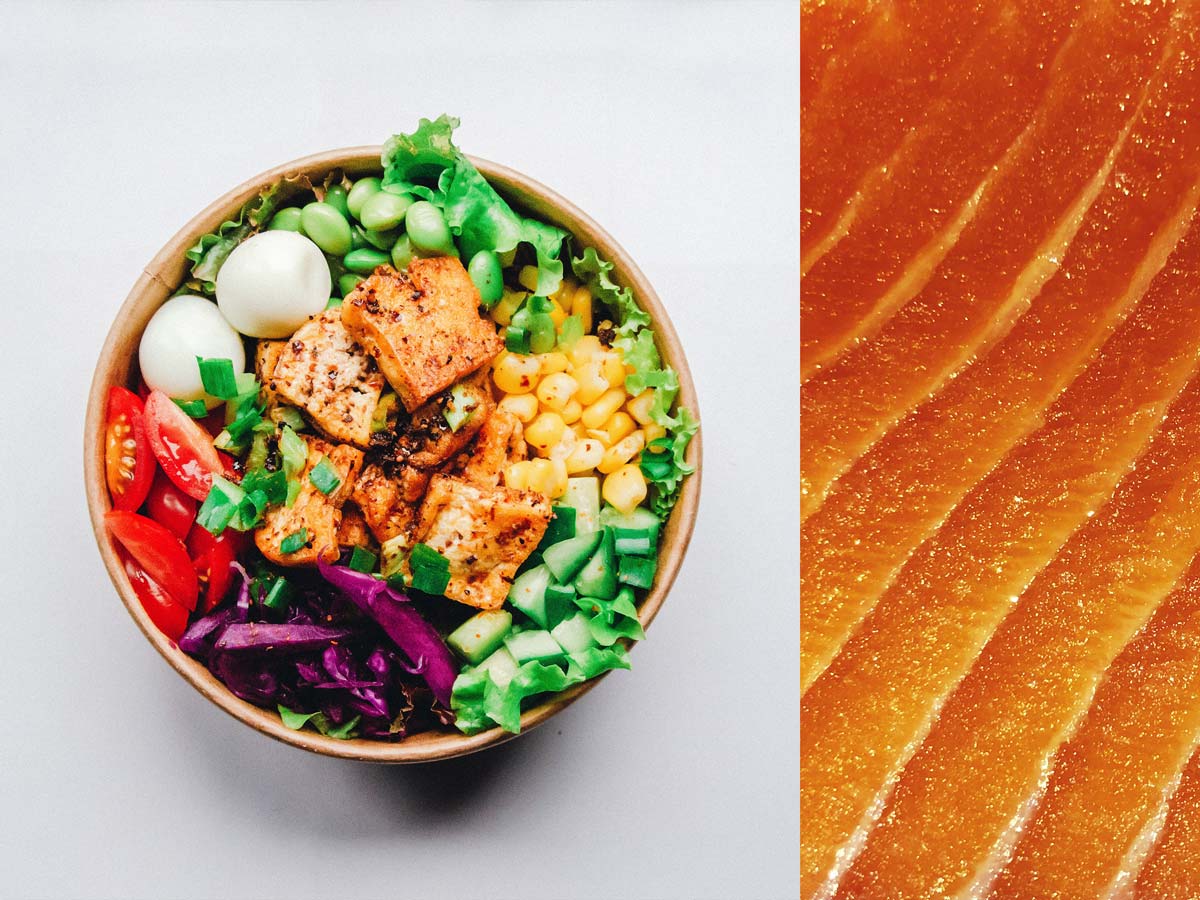

A near-perfect piece of protein is sizzling on your grill. Its texture, taste and appearance all mimic your favourite cut of meat, like a salmon fillet, a chicken breast or a juicy steak, turning plant protein into a delicious entrée.

Toronto Metropolitan University (TMU) food science professor Dérick Rousseau is collaborating with startup New School Foods, which is led by CEO and founder Chris Bryson, on developing a process that emulates the appearance and experience of purchasing, cooking and eating a “whole muscle” meat. Rather than ground or canned processed-type meat replacements, the product reproduces a plant-based version of a beef steak or salmon fillet. They have secured a patent for their process, and their salmon fillet prototype has earned them a place on the list of semifinalists for the $15 million international, multi-year XPRIZE Feed the Next Billion competition.

CEO Bryson reached out to professor Rousseau, one of Canada’s leading food scientists. Professor Rousseau’s lab, the Food and Soft Materials Research Group, focuses on food structure. “I wanted to contribute to his vision and use the strengths that we have in my lab to see if we could create, like de novo create, what would amount to a very first prototype of a salmon fillet,” said professor Rousseau. This involved creating a structure that goes beyond the appearance of meat—they wanted to recreate meat’s fibrous texture, along with providing a similar protein level and a consumer experience that mirrors what it would be for animal protein. Inventing a product that looks, cooks and flakes just like the meat equivalents is critical. “If you have a product that requires [the consumer] to go back to school to learn how to cook … it’s not going to get the same level of adoption,” said Bryson. “We really want to make it easier for people to pick the plant-based option.”

To develop their prototype, professor Rousseau and his lab, including postdoctoral fellow Auke de Vries, started at the molecular level by developing a proprietary process that transforms biopolymer gels into platforms, which mimic the fibrous nature and texture of meat. Then, they freeze the solution, though the process is more complex than simply turning down the temperature. This patented freeze-based process allows them to align the solution’s molecules. They have structured the plant-based salmon fillet so that, like a fillet of fish and under similar cooking conditions, it transforms from a raw, semi-translucent state to opaque when prepared. While their prototypes are salmon equivalents, they note that the technique will have applications to a wide variety of meats.

The next stage of the XPRIZE process is expected to occur in January 2023. Meanwhile, professor Rousseau, Bryson and their teams continue to work to perfect their product, and New School Foods is being incubated in TMU’s Science Discovery Zone. The collaboration extends to other parts of the TMU community, such as the Design + Technology LAB, led by director and professor Jonathon Anderson, which has built pieces of equipment for this project.

We really want to make it easier for people to pick the plant-based option.

Learn more about New School Foods (external link, opens in new window) .

Learn more about the Food and Soft Materials Research Group (opens in new window) .

This project has received support from Mitacs and from Protein Industries Canada.