From research to rinks: How science is shaping a more sustainable ice industry

This article was originally published in the May/June 2025 issue of RINK Magazine, the official trade publication of the United States Ice Rink Association (external link) . The United States Ice Rink Association serves the North American ice rink industry, offering insights, news, and resources for industry professionals.

More sustainable ice rinks are on the way thanks to scientific research being catalyzed by an innovative industry-academia collaboration.

Dr. Stefania Impellizzeri, a materials chemist at Toronto Metropolitan University (TMU, is applying scientific, data-driven and evidence-based methodologies to investigate new ways to enhance the sustainability of ice rink operations. Focusing on everything from optimizing ice preparation and conditions for different activities, to producing more eco-friendly yet high-performance ice paint, to efficiently recovering meltwater, Impellizzeri’s goal is to use rigorous scientific approaches to inform best practices for high-efficiency and sustainable ice-making.

Impellizzeri’s research is supported by Jet Ice, a leading provider of products and services for the ice-making industry in Canada and around the world. This research is also supported by the Natural Sciences and Engineering Research Council of Canada (NSERC) Alliance grant program.

“This is really what’s behind the Jet Ice and TMU research partnership — leading the way in reshaping how the industry and facilities approach their operations,” says Impellizzeri, a professor in the Department of Chemistry and Biology who, in 2022, became TMU’s inaugural Jet Ice Research Chair in Sustainable Materials Chemistry. “By leveraging results grounded in scientific principles, we will develop solutions that enhance the performance of ice while also making rinks more environmentally friendly. Improving efficiency while also aligning with the latest industry standards will result in smarter, more sustainable operations.”

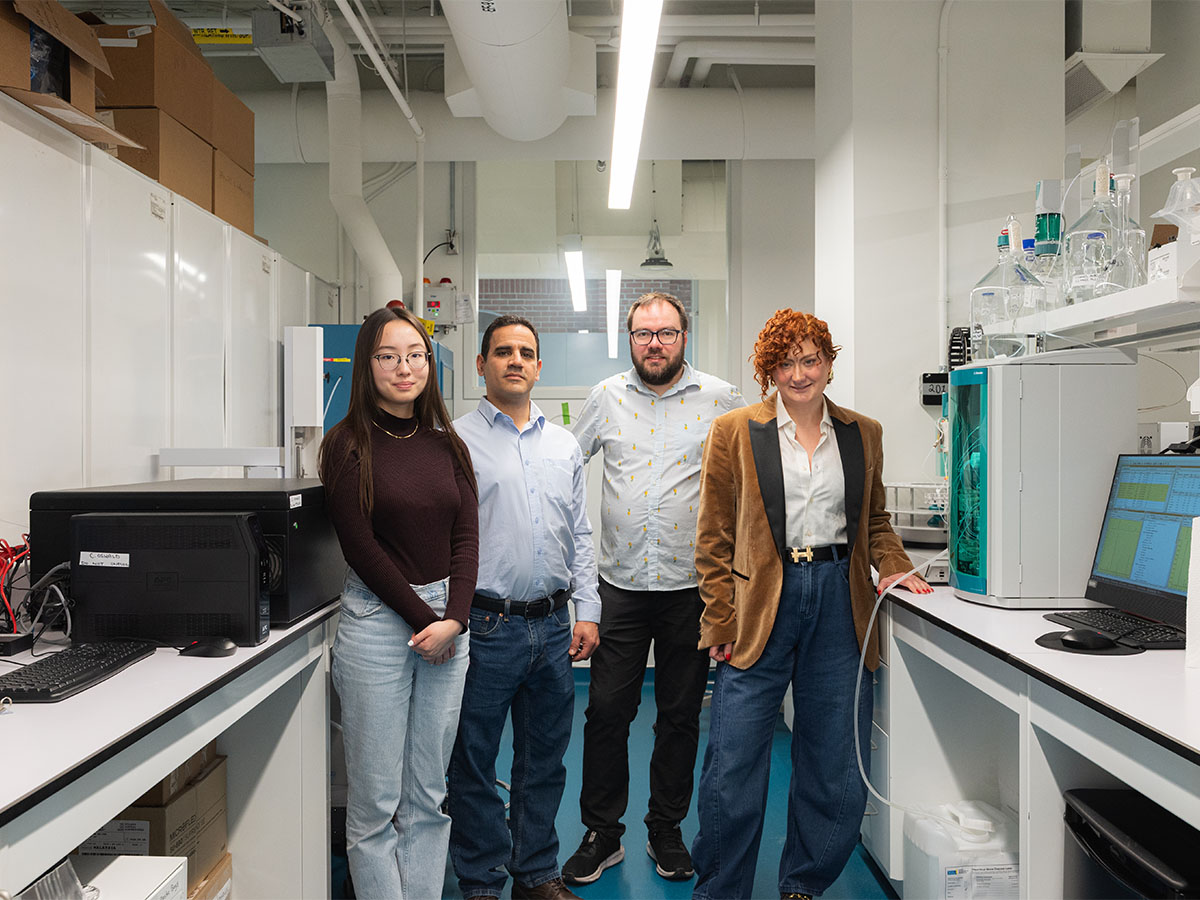

Dr. Impellizzeri and members of her research group in the Water Analysis Lab.

Canada’s almost 8,000 indoor and outdoor rinks use copious amounts of water to produce ice. Greening ice rinks is key to achieving Canada’s goal of net-zero emissions by 2050, and the United Nations’ sustainable development goals for energy and water. The National Hockey League (NHL) has responded with the Greener Rinks initiative, which invites hockey arenas across the globe to improve their environmental impact through a variety of sustainable solutions. To support community ice rinks, which have more limited budgets than the NHL, Jet Ice invested in Impellizzeri’s research to advance affordable, practical and evidence-based solutions the entire industry can use to decarbonize its operations.

“By supporting the generation of scientifically backed data, we can take more proactive steps to make our rinks more sustainable moving forward,” says Greg Taylor, chief operating officer at Jet Ice.

Impellizzeri’s research involves studying required ice conditions for hockey, curling, skating and other such activities. She and her team surveyed ice arena managers in North America to identify their views on ideal ice temperatures and reviewed existing literature on best practices to manage ice surfaces. (external link) The results support their experimental research on optimal ice surfaces for performance and energy use that factor in ice and air temperature, air humidity, ice thickness and water quality.

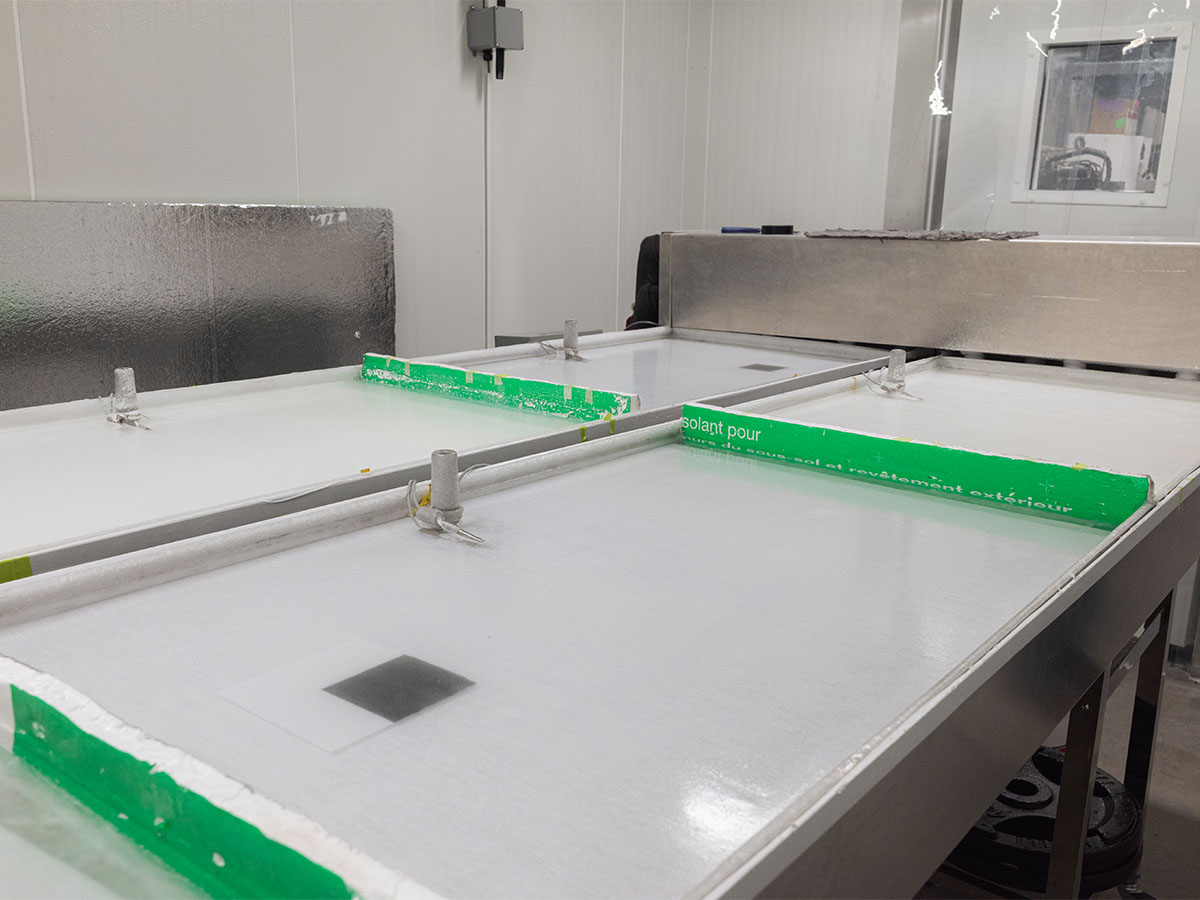

These scientific investigations take place at Impellizzeri’s state-of-the-art lab, which includes a 15-ft. by nine-ft. purpose-built ice rink that allows for systematically controlling conditions such as humidity and air temperature. Their efforts have revealed how water quality can affect ice properties such as slipperiness, stickiness, friction and frost formation. To help the industry apply these findings, Impellizzeri’s team is also developing affordable ice-testing kits for rink managers to optimize their ice surface conditions.

The research-grade experimental rink simulator is enclosed in a 15-foot by 9-foot refrigerated chamber built to maintain the temperature and humidity of the cooling plates using computerized controls. This 'ice lab' is a cutting-edge R&D facility uniquely tailored to real-world and industry needs.

The experimental rink is a controlled environment designed for testing ice paints, resurfacing techniques, and the impact of water treatment and materials on ice quality and rink energy expenditure. The ice is monitored in real-time with sensors that measure the variables involved in high-performance ice-making.

The Water Analysis lab is a precision testing facility equipped with advanced analytical instruments to measure a wide range of water and gas properties.

Also being explored by Impellizzeri are the ice shavings produced by resurfacers that are typically dumped outside arenas. Her team found they contain microplastics, chemicals and other nanoengineered materials that can contaminate local soil and affect water quality. The data can inform how to safely dispose of these shavings and support additional research on removing the contaminants to reclaim clean water. Meanwhile, there is the end-of-season ice waste, which contains the residue of ice paint used both under the ice and on its surface to add logos and mark play zones. The separation of paint residue from meltwater typically takes days, but Impellizzeri’s team developed a new eco-friendly additive that shrinks this process to just 30 minutes. At the same time, experiments are underway to identify green yet high-performance materials for ice paint. All of these investigations, Impellizzeri says, could lead to cleaner wastewater that could be repurposed for sanitation, cooling or other uses.

“With an evidence-based approach, we can improve the performance of ice and support rink operations in being more efficient and environmentally sustainable,” Impellizzeri says. “By prioritizing standards based on science, we can drive meaningful, lasting improvements in ice-making and rink sustainability.”

Learn more about this research and for latest updates, visit torontomu.ca/jet-ice.

Related stories