EngSpotlight Interview: Mechanical Engineering

Hi, my name is Ruth, and I did Mechanical Engineering at TMU. One of my interesting facts is that I am very familiar with Ratatouille. It’s one of my favorite movies, and I can recite most, if not all, of the script by heart.

Why Mechanical Engineering?

I really think that Mechanical Engineering was where I ended up because it allowed me to make the least amount of decisions possible in my initial, early career days. So, I wasn’t sure what, in specific, I wanted to do for the rest of my life. And what I loved about Mechanical is that you can go into Solid Mechanics, you can go into Thermal or Fluids, really, whatever you want. You can do Electromechanical as well, or Biomedical. There’s so many avenues that you can take it. And I was just so curious about the world around me and it gave me a really good opportunity to learn and then sort of make those decisions as I learned more about myself. I also really like the fact that with Mechanical you can choose a career path that allows you to do that very technical, at-the-compute, kind of work day. Or you can also choose to have more of a hands-on, in-the-field, applications sort of work days. So I like that you can have both, one or the other, and it was really a lot of choice that you get. So, that’s what brought me to Mechanical in specific, but honestly, I think I would have been happy anywhere in the Engineering discipline.

Watch the video of the interview!

What were the most challenging subjects for you in your transition to university?

During high school my focus was more on Biology because I was so certain I wanted to become a pediatric specialist at that time. And what really changed was that I had Physics one year in summer school and I learned that you actually can't get by just by memorizing things, the way you can with Biology. You need to really understand why things work the way they do and how they work. And I really loved that. So the transition from memorizing things what is in front of me versus understanding why they work the way that they do, came during university.

Another challenging subject for me in university were definitely the Math related ones, like heavy Calculus ones. And I did not necessarily enjoy them until I learnt what works best for me, in terms of how I learned. Honestly, the later into my degree I went, the more I loved my courses and the more I loved the content I was learning, and I think it was because it became a lot less theoretical and a lot less generic, or general. It became a lot more specific to the things that I can see an application for, and I can see sort of how it would be related into my day-to-day, and that really inspired me and striked this passion for me.

Current workplace: Mosaic

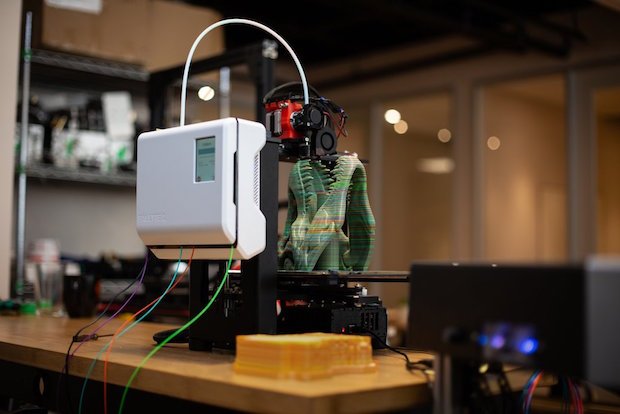

So Mosaic Manufacturing designs manufactures automated 3D printing solutions. So the mission is really to bring 3D printing and manufacturing to the factory floor, so what that means is that we have a really great future ahead of us where additive manufacturing is just beginning, and right it’s being used on a lot of smaller scale projects and hobbyist, things like that. But the potential to use 3D printing to really change the way we manufacture is huge.

Additive manufacturing has so much room to grow and to really revolutionize, not only sustainability but also just the overall efficiency of the way things are manufactured. So, Mosaic works on building 3D printers as well as 3D printing solutions that sort of challenge that scalable, vertical that the 3D industry’s having right now, of how can we do this on a larger scale, and faster, and more efficient, more effective, that sort of thing. And within Mosaic, the specific project that I’m working on and the team that I’m working with is really tackling the textile vertical so, it’s amazing that 3D printing can; you can print what feels like anything. Whether it’s wood filament, metal filament, plastics. You can even print things that look and feel like adhesive, or look and feel like fabric.

On the team I’m working as more like an application engineer, mechanical engineer side of things where we’re working on tackling the textile vertical. So, how can we make this, something that’s possible in a scalable way.

What attracted you to 3D printing in the Mechanical Engineering field?

This specific industry as a whole, looking at the broader scale, I’m really interested in additive manufacturing just as a sustainable solution to manufacturing. I had sort of a moral dilemma of when I was contemplating engineering in manufacturing, because I don’t like the idea of just producing stuff, more of things. But I do like the idea of producing it in a way that’s as eco-aware, sustainability-aware as possible. For me, with additive manufacturing, sustainability was a huge component to it. But then ultimately, it also was the idea that I could work on something that can really change the way that things are done in the world right now, and really revolutionize the way that we think about manufacturing and we think about the products that we’re creating. I think there’s a lot of room for engineers to sort of consider the impact of the products that they’re creating, and consider sort of how these products are being cycled through their entire life. And so, Mosaic does a really good job of really looking at that and working on that, in that area, so that’s something that really drew me to the company. That, along with just the really cool work that they do in here.

What is the best mindset for current students to develop about engineering?

It’s really weird because in school, there’s a right or wrong answer, right? It’s like you either have the answer or you don’t have the answer. So it is like a really strong mindset to break, I guess, the concept of right or wrong. It’s definitely something that was cultivated through extracurriculars. So, when I was on technical teams, every year we would be building the same thing, like a car. Whether it’s the outboard system of a car. But then, every year, something changes and that’s just a testament to the fact that the more you know the more your ideas can grow, and based off of what you’re building off of versus new constraints like, so much can change in the way some things are done. But also on the non-technical side of things, when we’re looking at some of the problems that we saw in the world, everybody had a different opinion on how things can be done or improved. And, often times, there’s also no right or wrong answer in those cases. It’s just a collective of different things that can work and can work together, or maybe not. And so, like if I only did school and didn’t really explore the extracurriculars and the different job opportunities, I might have graduated with a mindset that there is right and wrong answer, and if you don’t have the right answer, then you’re wrong. Which isn’t the case at all. Don’t think there’s a right or wrong answer in a lot of engineering problems, and if you don’t have a right answer, then great. Then you know that that’s not going to work, and you know where you can head because it’s anywhere but the way you’ve already tried so far.

Is there anything you would have done differently on your pathway to get where you are today?

I think my absolute top one thing I wished I did differently was just, be kinder to myself in the whole process. Completing any sort of university degree or like any sort of continuous learning is extremely demanding, and it’s very easy to get caught up in sort of like the face paced workflow of things, and needing to produce certain things. But I think it’s important to take that time to really think about yourself, and your health, your mental well-being, and the people around you, and just allow that to register to see what you need in the moment. Taking your time for yourself to check-in makes you better, able to serve yourself as well as your team. So, it’s honestly doing you a favour in both ways by taking a step back, and not being afraid to do that.

What advice do you have for engineering students?

I think in university, everybody feels like Engineering is either for you or it’s not, but I don’t think that’s actually the case. I went through waves where I felt like Mechanical was for me and I’d be great at it, but also waves where I was like Mechanical feels like it’s for me BUT I don’t know that I’ll be great at it. And I think what it comes down to is just being willing to fail and then being willing to learn from those mistakes and pick yourself up, and learn like, “What did I do wrong? How could I have done it better?” If you can figure out how you learn and what works for you, that’s all it matters. It’s not someone telling you like, “Read the textbook beginning to end” or “Take notes on absolutely everything,” because maybe you just need to do a lot of problem-solving, a lot of questions. So this is a bit of like study advice I guess, but just, in general, the major piece of advice I give to a student struggling with their courses or even just nervous to head into their courses is just, “Learn the way that you learn and then stick to it, and learn what works for you. Don’t be afraid to ask questions. You might feel dumb when you’re asking them, but you’ll feel so much better once you actually know the answer to those questions. And chances are there’s somebody else in the room that has the exact same question as you, but is, you know, nervous to ask.” I’ve definitely learned the hard way that there really is no such thing as a dumb question, and that the only way you can learn is by asking these questions, and by being curious, and allowing yourself to be curious, and getting rid of that self-talk that tells you not to be curious about certain things or tells you not to be the person that puts their hand up in class. It is okay, and it’ll actually be better for you.