Facilities & Testing

AERIAS is equipped with the infrastructure and technology to simulate, analyze, test, and refine aerospace components, systems, and environments.

Our labs are purpose-built for prototyping, simulation, and real-time testing. From early concepts to complex models, our facilities are purpose-built to help you solve real-world engineering problems, no matter the size of your challenge. Whether you're analyzing engineering issues, testing winglets, or developing cabin tech, we provide the space, tools, and guidance to get it done right.

Need a custom test setup?

We can build custom rigs, conduct materials and strength testing, and more, for unique scenarios.

Facilities and equipment include:

- Reconfigurable full-scale cabin mockup

- Advanced space dynamics and control test facility

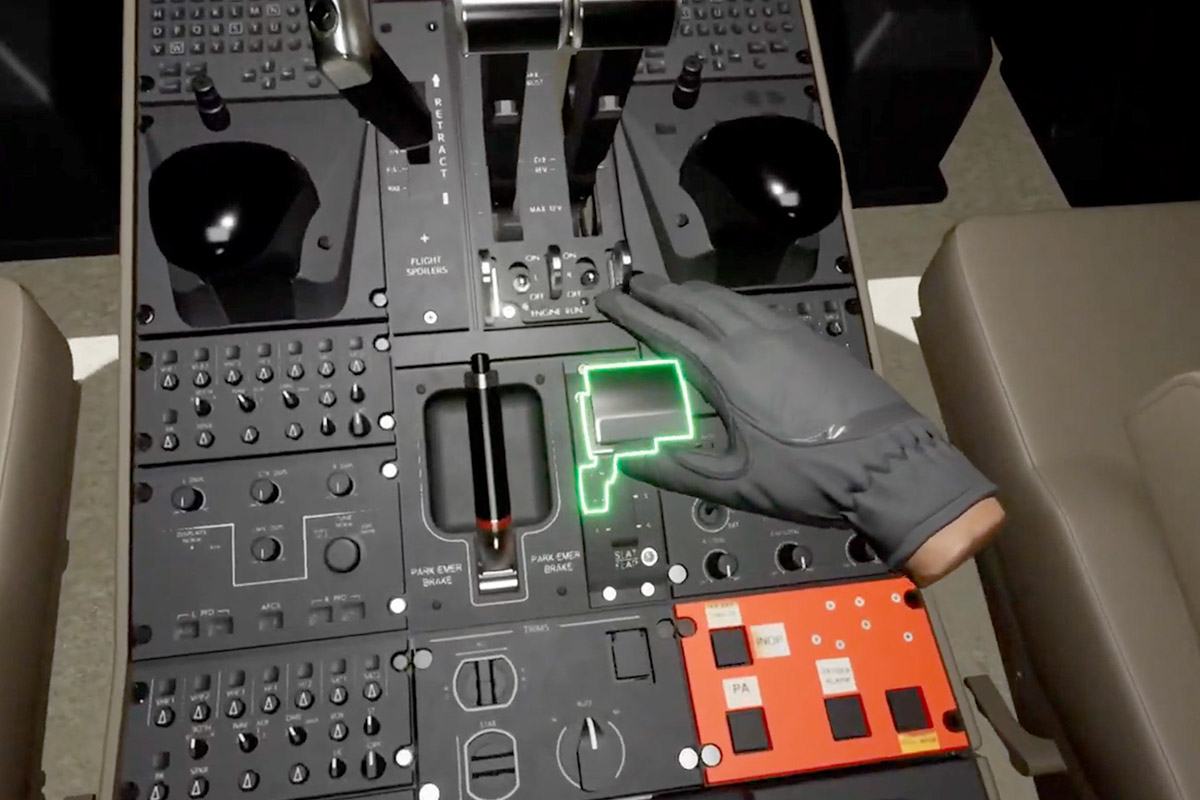

- Augmented reality motion simulation lab

- Light disinfection performance test rig

- Cabin air seeding testing apparatus

- Frictionless space environment

- Baggage bay test rig

- UAV development lab

- Orbiting satellite space communication antenna

- State-of-the-art numerical modelling and simulation software

Laboratory and testing facilities

We offer quick testing and analysis of materials, aerodynamics, and simple structures. Our testing capabilities include:

Used for:

Measuring aerodynamic performance, sensor performance, and simulating propeller performance.

Specs & features:

- Test section size: 3 ft by 2.5 ft

- Maximum speed: Mach 0.2

- Includes lift, drag, moment transducers

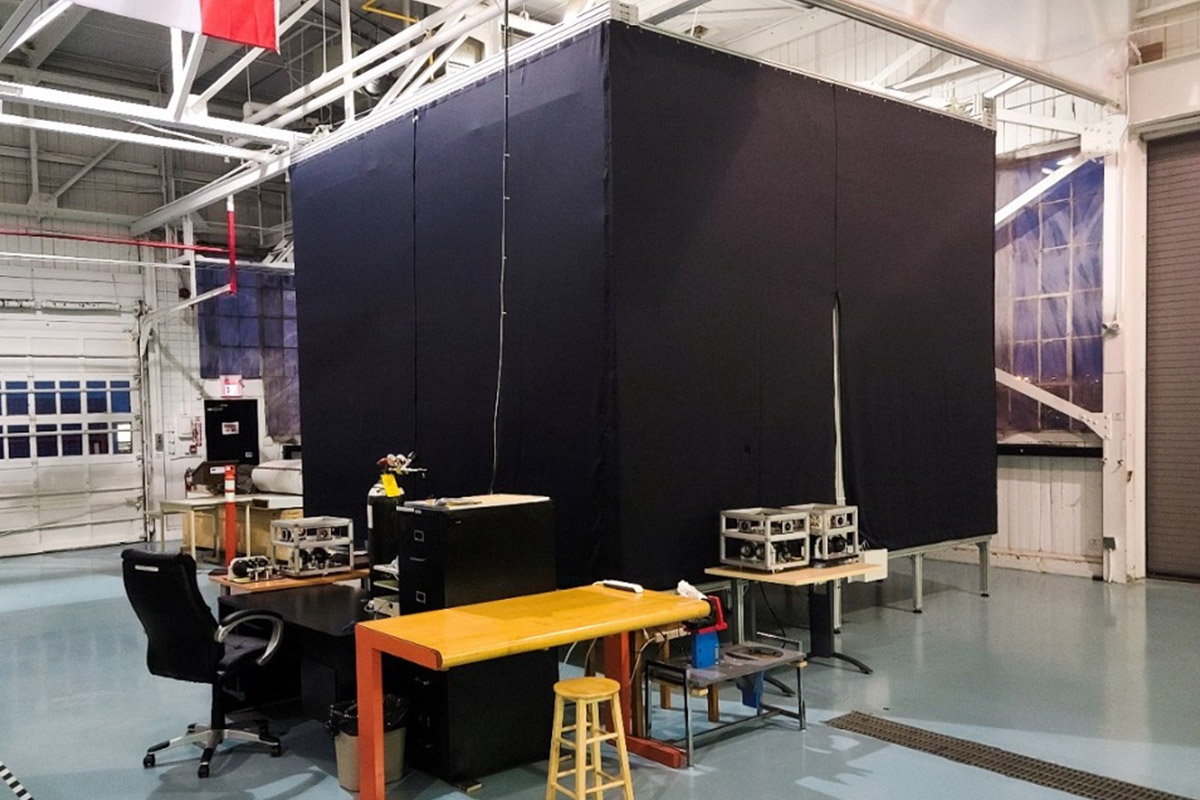

Used for:

Research related to cabin noise, local noise cancellation, LCD windows and panels, cabin environment, and passenger comfort.

Specs & features:

- Configures to emulate Airbus A220 or GE 7500

- Size: 40 ft by 11 ft

- Contains galley and lavatory

Used for:

Testing cables.

Specs & features:

- 7000 sq ft lab

- Equipped with a strong floor to anchor structures to the floor for testing.

- Includes electro mechanical testing machine and in-house additive manufacturing system

Used for:

Testing the reliability and safety of samples.

Specs & features:

- 50 kip capacity with extensometer and hydraulic grips

- Capable of monotonic and fatigue loading

- Includes heat chamber for high temperature testing

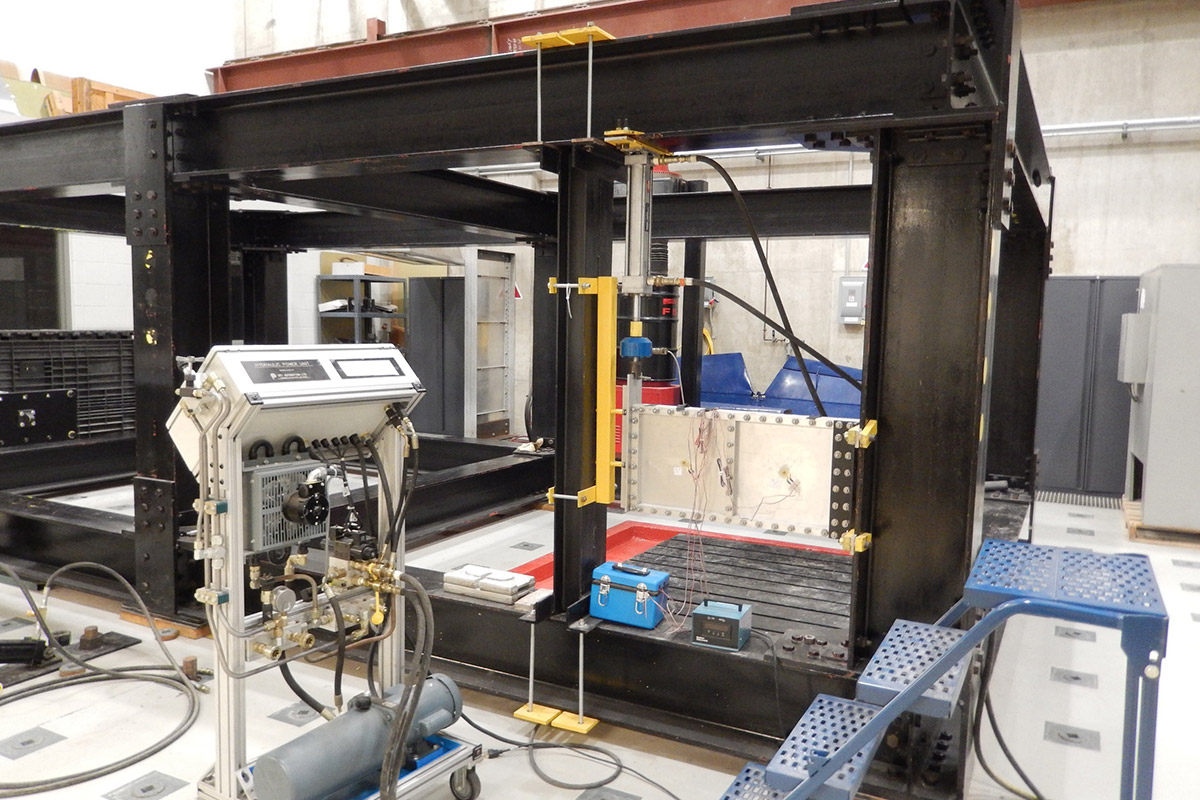

Used for:

Testing actual structural components and strain sensors and for measuring structural deflection.

Specs & features:

- Rigid frame for anchoring hydraulic actuators

- Size: 7 ft by 10 ft by 20 ft

Used for:

Testing temperature profiles over long periods of time and providing long term heat treatment to various materials.

Specs & features:

- Two 4 ft by 2.5 ft materials treatment ovens

- Explosion proof/vented

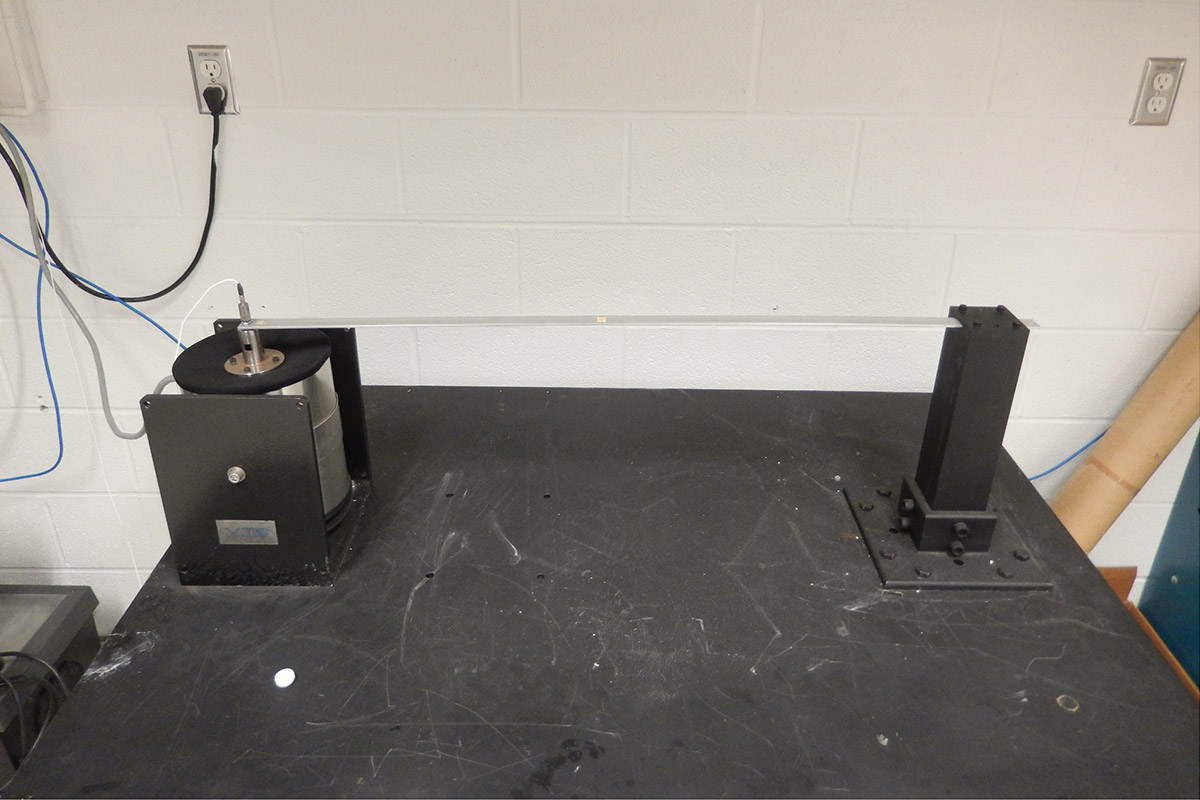

Used for:

Assessing the fatigue life of various materials and configurations.

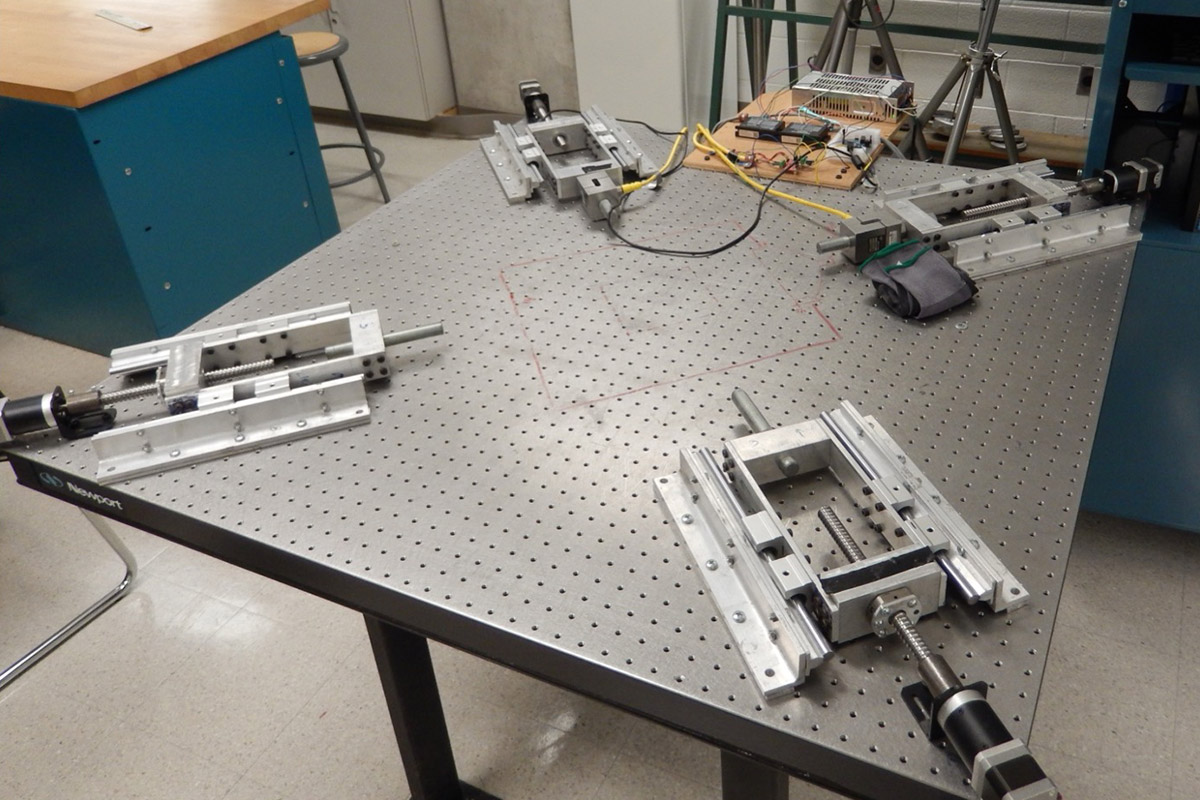

Used for:

Performing experiments in autonomous inspection, servicing, and assembly of large space structures.

Specs & features:

- Large flat table

- Includes free-flying robotic spacecraft for testing

Used for:

Multidisciplinary design optimization for aerospace concepts, aircraft maintenance procedures, transport systems, and training programs within virtual and augmented reality environments.

Specs & features:

- Enhanced Haptic-Based Virtual Reality Ground Control Station (HVR-GCS)

- Photorealistic extended reality-based flight simulator for urban air mobility operations

- AI-enabled Metaverse campus for immersive training

Your Innovation. Your IP. Your Terms.

Whether you're launching a short-term proof of concept or a long-term development program, we tailor each partnership to fit your goals. Our flexible contract structures allow you to retain your intellectual property, while benefiting from the expertise, infrastructure, and talent of a full-scale innovation centre.