Suspension Design and Dynamic Analysis Using ADAMS:

Suspension Design and Dynamic Analysis Using ADAMS:

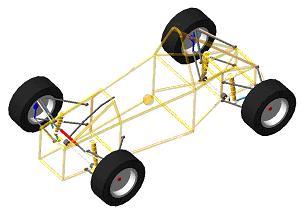

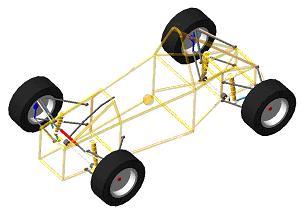

By using ADAMS simulation software, our team was able to save approximately 2 weeks of abstract testing time and about $5000. If time and funding allows we will use these extra 2 weeks to fine tune our vehicle using the settings found throughout the ADAMS simulation software as our basis. The analyzed system comprised of outboard and vertically mounted push-rod actuated dampers with unequal-length A-arms. The model used was a simple tube representation of our chassis. The chassis shown is only a visual representation; our 2003 chassis is actually a carbon fibre monocoque.

Simulation on the Ryerson FSAE car entailed static suspension analysis which monitored roll center migration, camber/caster movement, etc. Using these results, we were able to investigate what changes should be made for next years suspension design. The suspension was already built at the time of simulation so we could not modify the 2003 hard-points.

Dynamic testing of the vehicle told us what spring rates to use, damper settings, ride height, camber and caster settings, as well as toe angle. Of course we donít expect to set up our car exactly like the simulation data shows (because of track surface, temperature etc), but it will make an extremely decent starting point to test. As mentioned; rather than beginning testing from an abstract set-up we will begin with settings proposed by the ADAMS simulation.

Another advantage to using software is that we have a large collection of data telling us what the vehicle will do when a change is made. Again, this will not be 100% accurate, but the changes will have a drastically higher probability of correctness.

Simulation is the next step in engineering development. Our team strongly recommends performing ADAMS analysis on any FSAE vehicles before hitting the track, and if possible, integrate the analysis into the design process (this is where the capabilities of ADAMS are most advantageous). The analysis helped change tire forces to a more even left-right weight distribution during cornering which will help maximize cornering speeds and reduce tire wear. Simple analysis was done on static parameters such as roll center (results are shown below).

Suspension Design and Dynamic Analysis Using ADAMS:

Suspension Design and Dynamic Analysis Using ADAMS: By using ADAMS simulation software, our team was able to save approximately 2 weeks of abstract testing time and about $5000. If time and funding allows we will use these extra 2 weeks to fine tune our vehicle using the settings found throughout the ADAMS simulation software as our basis. The analyzed system comprised of outboard and vertically mounted push-rod actuated dampers with unequal-length A-arms. The model used was a simple tube representation of our chassis. The chassis shown is only a visual representation; our 2003 chassis is actually a carbon fibre monocoque.

By using ADAMS simulation software, our team was able to save approximately 2 weeks of abstract testing time and about $5000. If time and funding allows we will use these extra 2 weeks to fine tune our vehicle using the settings found throughout the ADAMS simulation software as our basis. The analyzed system comprised of outboard and vertically mounted push-rod actuated dampers with unequal-length A-arms. The model used was a simple tube representation of our chassis. The chassis shown is only a visual representation; our 2003 chassis is actually a carbon fibre monocoque.