Modular Rear-End

Modular Rear-End

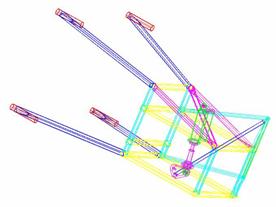

The modular rear-end was designed using Solid Edge and CadKEY. During the design of the modular rear-end, emphasis was placed on the axial and torsional rigidity of the structure. The need for a detachable engine compartment also dictated various design characteristics of the modular rear-end. Placement of hard points within the chassis during lay-up needed careful attention in order to assure proper design geometry and proper assembly.

The modular rear-end was constructed using high strength cromoly steel tubing (1” outside diameter). Assembly was performed with the aid of a jig. Individual tubes were welded using a TIG welder, provided by Lincoln Electric.

Modular Rear-End

Modular Rear-End