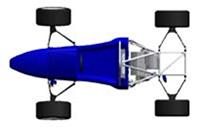

The 2003 chassis was designed using Solid Edge. The completed design was then analyzed and a male mould was CNC machined from a solid piece of high-density foam at Webber Manufacturing. The male plugs were then used to create female fibreglass moulds. Both the plugs and the fibreglass female moulds were then taken to Multimatic, where the composite monocoque was created.

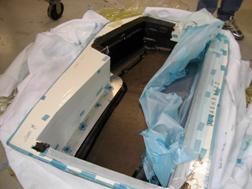

The process of laying up the pre-pregnated carbon-fibre was tedious due to the various hard points and the need to ensure a strong structure. The cross-section of the monocoque was composed of 3 outside layers of pre-pregnated carbon-fibre, a ½” sheet of nomex or aluminium honeycomb (depending on location) and 3 inside layers of pre-pregnated carbon-fibre.

The 2003 chassis was designed using Solid Edge. The completed design was then analyzed and a male mould was CNC machined from a solid piece of high-density foam at Webber Manufacturing. The male plugs were then used to create female fibreglass moulds. Both the plugs and the fibreglass female moulds were then taken to Multimatic, where the composite monocoque was created.

The 2003 chassis was designed using Solid Edge. The completed design was then analyzed and a male mould was CNC machined from a solid piece of high-density foam at Webber Manufacturing. The male plugs were then used to create female fibreglass moulds. Both the plugs and the fibreglass female moulds were then taken to Multimatic, where the composite monocoque was created.