Heat and power — combined for climate and community

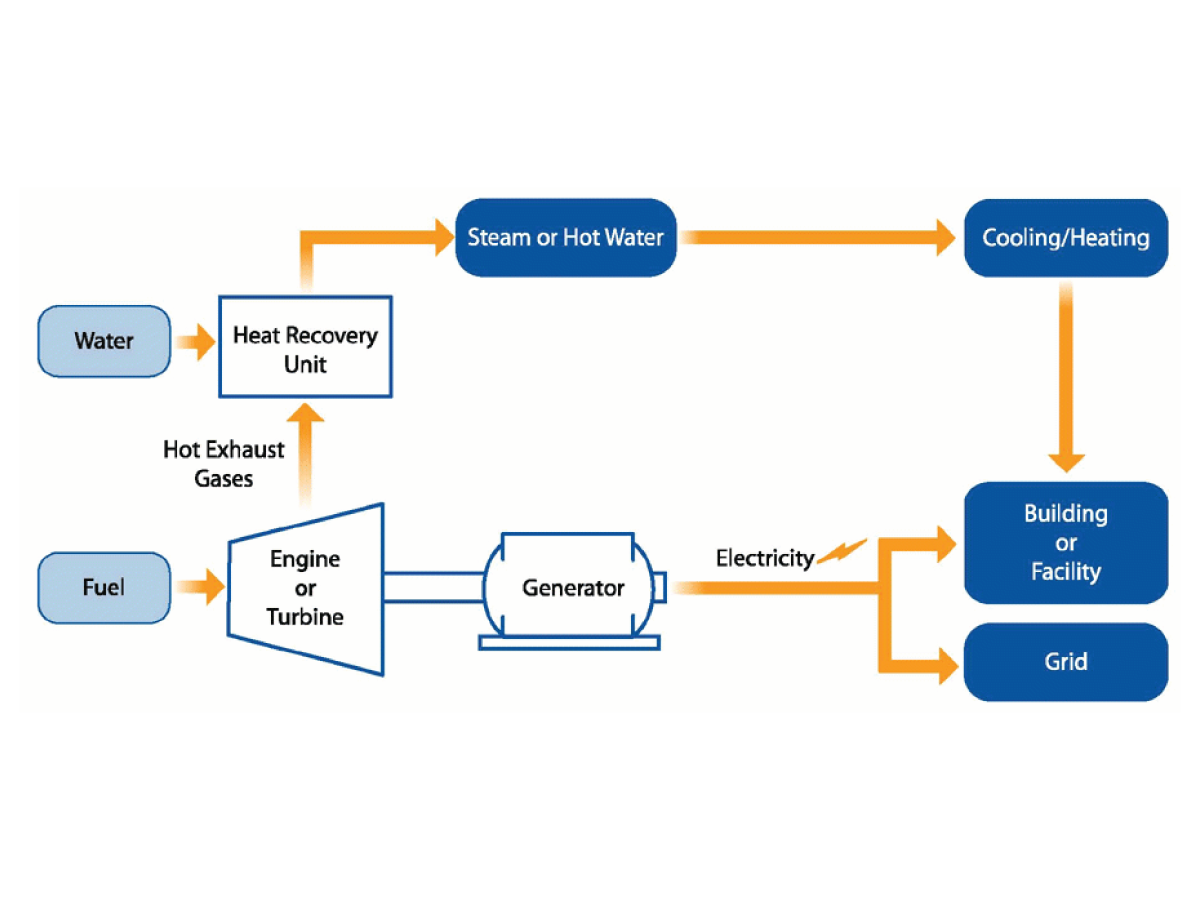

Cogeneration, or combined heat and power (CHP), is the useful utilization of heat released from a single fuel source in a power generating station (as depicted in Figure 1 below). In the traditional model, heat generated is left to waste. In a cogeneration system, however, this waste heat is recovered and utilized for various different activities such as space or water heating and cooling. This in turn leads to an increase in the efficiency of the plant as previously wasted energy is now brought into play. This leads to savings of not only the fuel source, but also, importantly, greenhouse gas (GHG) emissions that result from the burning of fossil fuels.

Figure 1. Source: EPA (external link, opens in new window) .

CHP systems can be used in various scenarios, both residential and industrial. Some examples from Ontario include (PDF file) Thunder Bay's wastewater treatment plant which installed a CHP system that has led to energy and cost savings of around $400,000 over its first year. Sudbury Region Hospital (external link) also installed a CHP plant which produces 6 MW of energy. These examples are small-scale and on a community level. Large-scale cogeneration plants, on the other hand, can meet the needs of entire grids. One of the largest is in Midland, Michigan, which produces about 30 per cent of the energy needs of the state's lower peninsula.

Community energy and CHP

Municipal leaders are facing growing economic, social and sustainability challenges and are increasingly turning to local energy production as a means of addressing them. Community energy plans are an important model to meet increasing local energy demand and encourage citizen participation in decision making. CHP targets are now being built into many community energy plans, such as the one developed by the (PDF file) Municipality of Guelph (external link) , which plans to have 30 per cent of its demand met through CHP by 2031.

As technology improves and modular and pre-packaged systems become more readily available, relatively small-scale private investment and ownership in CHP has become possible, leading to community-scale projects. These projects can take different forms and have different levels of community ownership. Examples include investment through community bonds, managerial control by or on behalf of members of the public and partnerships with industry.

Cogeneration and resilience

Cogeneration facilities can lead to local economic development for communities and, due to shorter transmission and distribution distances, also increase resilience of the overall electricity system. This is especially useful in extreme weather conditions, where faults far away can cause disruption of power to a whole region. CHP can form an integral part of microgrids, as well as district energy systems, which can be isolated from the main grid in the event of its failure, maintaining power for the community at some level and to critical customers.

Thus we can see that CHP is an effective technology that can be used to help address climate change concerns, especially as a transitionary technology while the world shifts to greener sources of energy.

The U.S. aims to add 40 GW of CHP by 2020 (external link) . According to estimates, meeting this target would lead to a saving of one per cent of energy use and emissions reductions equivalent to taking 25 million cars off the road (EPA, 2012). Canada too should create a better policy environment to increase energy production using CHP systems. In light of the Paris accord and tough targets ahead, this will help Canada fulfill its obligations and lead to an increase in energy conservation as well. Creating provincial, federal and municipal targets along with incentives is imperative if Canada is to achieve a much higher adoption of CHP technologies.